Principle of Operation

The Sultan Flow measurement system operates by transmitting an ultrasonic signal from its transducer towards the liquid being monitored. The reflected signal or echo is received by the transducer and processed. The time between transmission of the ultrasonic signal and reception of the echo is measured, and using the speed of sound through air, the distance from the transducer to the liquid level is calculated. Flow through the channel or structure is then calculated from the level measurement and the user entered properties of the channel.

The Sultan Flow system uses sophisticated software to locate and track the correct echo without being affected by echos from fixed objects or changes in the liquid surface. When the liquid level or surface conditions change, the system follows preselected signal tracking parameters. In the event of a total loss of signal, the system adopts signal recovery routines to relocate the correct liquid level.

The system employs automatic gain control to compensate for changes in echo amplitude due to variations in environmental conditions. Continuous current, voltage and relay outputs are provided. These outputs can be programmed for failsafe conditions in the event of a loss of signal or system malfunction.

Features

- Optimized frequency selections to suit the application environment.

- Capable of monitoring liquid flow under the most difficult conditions

- Real time diagnostic display

- Flexible, multi point or calculated scaling of display and outputs.

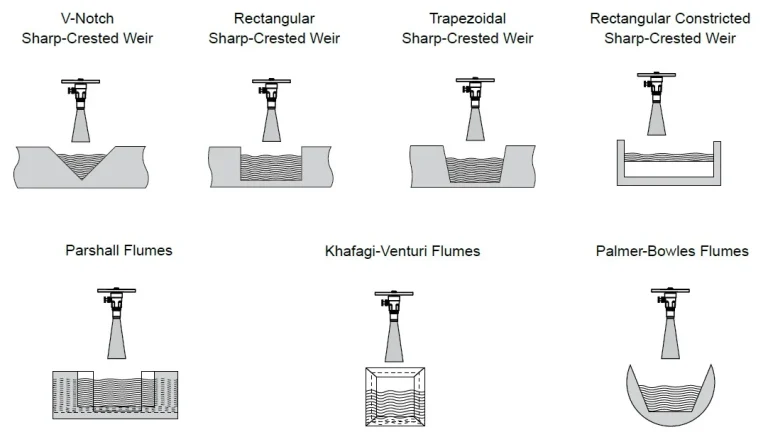

- Suits a broad range of flumes, weirs and flow control structures

- Programmable totalizer

- Programmable pulse per flow output

- Programmable failsafe mode

- Fast acting temperature compensation

- 3G remote setup options and configuration

- 4-20mA, HART, Modbus, Goshawk with 32-point flow table (via PC)

Certifications

CE, ATEX, CSA (Remote Transducer)

Conforms to Brittish standards for flow calculations

Primary Applications

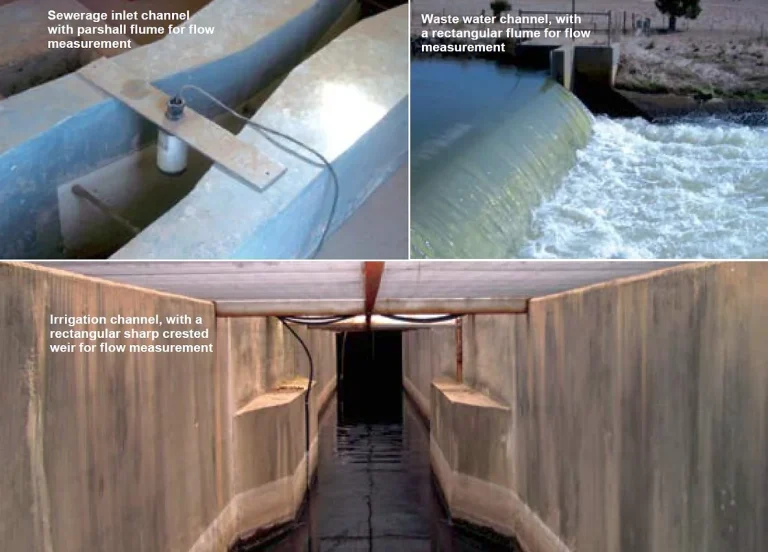

- Open Channel Flow

- Water treatment

- Sewage treatment

- Irrigation

- Industrial waste water

- Power waste water

- Environmental monitoring

- Special flow requirements for unusual flow channels

Primary Areas of Application

AWRT30/40/50 (T6)

AWRT30T4 & AWRT20

AWRT30T4 & AWRT20

Specification

Frequency

• 20kHz, 30kHz, 40kHz, 50kHz

Operating Voltage

• 12 – 30VDC (residual ripple no greater than 100mV)

• 36-60VDC

• 90 – 265VAC 50/60Hz

Power Consumption

• <3W @ 24VDC

• <6W @ 48VDC

• <10VA @ 240VAC

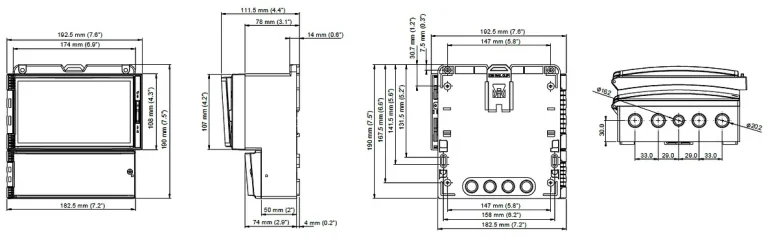

Analog Output

• 4 -20mA

(750 ohms @ 24Vdc User supply, 250 ohms internally driven)

Communications

• Goshawk, HART, Modbus, Profibus DP, Device Net

(Foundation Fieldbus & Profibus PA pending)

• Multi Drop mode can address 1-250 units over 4 wires

Relay Outputs: (5)

• Form ‘C’ (SPDT) contacts, rated 0.5A at 240Vac non-inductive.

• All relays have independently adjustable dead bands.

• Remote failsafe test facility for one relay.

Blanking Distance

• 50kHz = 0.25 m (10”)

• 40kHz = 0.30 m (12”)

• 30kHz = 0.35 m (14”)

• 20kHz = 0.45 m (17”)

Maximum Range

• 5 m (16ft) 50kHz liquids

• 7 m (22ft) 40kHz liquids

• 10 m (33ft) 30kHz liquids

• 20 m (65ft) 20kHz liquids

Resolution

• 1 mm (0.04”) 50, 40, 30,20 kHz

Electronic Accuracy

• +/- 0.25% of maximum range

Operating Temperature

• Remote electronics -40°C (-40°F) to 80°C (176°F)

• Remote transducer -40°C (-40°F) to 80°C (176°F)

Transducer/Amplifier Separation

• up to 1000m (3281ft) using appropriate RS485 cable

Cable

• 4 conductor shielded twisted pair instrument cable

• Conductor size dependent on cable length.

• BELDEN 3084A, DEKORON or equivalent.

• Max: BELDEN 3084A = 500m (1640 ft)

• Max: DEKORON IED183AA002 = 350m (980 ft)

Maximum Operating Pressure

• +/- 7.5 PSI (+/- 0.5 Bar)

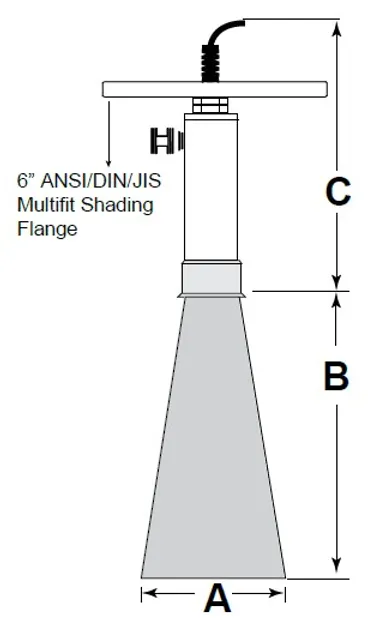

Beam Angle

• 7.5° without focaliser 50kHz/40kHz/30kHz

• 4° with focaliser 50kHz/40kHz

• 6° with focaliser 30kHz/20kHz

Display

• 2 line x 12 character alphanumeric LCD

• LED Back-lit display

Memory

• Non-Volatile (No backup battery required)

• >10 years data retention

Enclosure Sealing

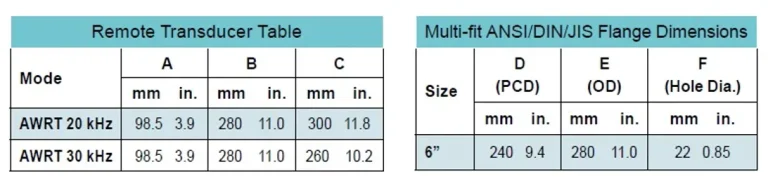

• Remote Electronics IP65 (Nema 4x)

• Remote Transducer IP68

Cable Entries

• Remote: 3 x 20mm, 1 x 16mm knock outs.

Mounting

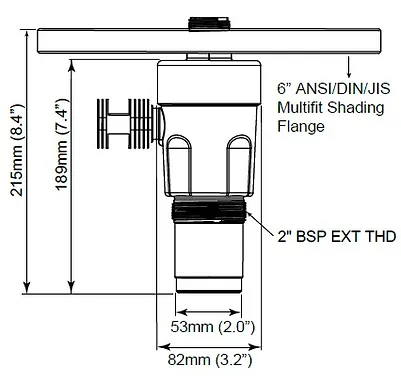

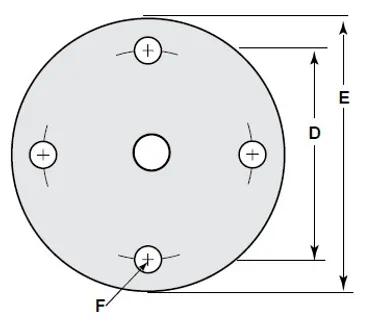

• 6” Multifit ANSI/DIN/JIS Flange

Typical Weight

Sultan AW System with appropriate flange and cone

Frequency (in kHz) kg lb

20/30 20 or 30kHz (3”) Transducer 3 6.6

30/40/50 30 (2”), 40 or 50kHz Transducer 1 2.2

Configuration kg lb

R6 Remote system with 6m cable 1 2.2

R15 Remote system with 15m cable 3 6.6

R30 Remote system with 30 m cable 6 13.2

R50 Remote system with 50m cable 10 22.0