On this page are just a few examples of Rheonik meter installations from around the world. Rheonik meters are used every day in just about every industry globally, providing real time input into process and measurement systems.

Reliability is key— Rheonik Coriolis meters have no moving parts to wear or plug and are suited to both gas and liquid streams. The ability to work across a wide range of flow rates and process conditions dramatically lowers installation and operation costs.

Safety is built into all systems. Low power usage makes all Rheonik meters intrinsically safe, and all meters are proof tested to 1. Sx their maximum operating pressure before shipment.

With highly accurate measurement performance and high-pressure capabilities, Rheonik meters are a natural choice for so many applications and quickly provide payback through improved product quality and greatly reduced maintenance.

Whether used for transfer, batching, process feed or control, Rheonik meters can provide online flow and density measurement. Like all of our customers, you can be assured of a value-for-money flow measurement solution from Rheonik for every application.

What is a Coriolis flow meter?

These meters are known to be extremely accurate and repeatable under a wide range of conditions and are a common sight in industrial applications where precision control is required. The Coriolis principle enables direct measurement of density and mass flow.

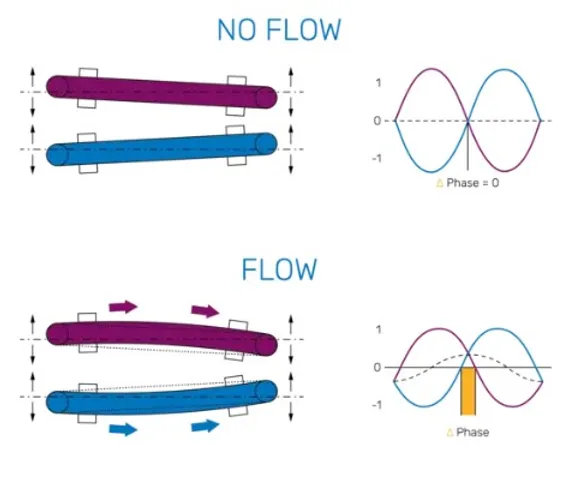

Coriolis flow meters work on the principle that the inertia created by fluid flowing through an oscillating tube causes the tube to twist in proportion to mass flowrate. Common Coriolis flow meters have two tubes. Measuring the sine waves allows us to directly measure mass flow. The measurement is independent of viscosity which means that users do not require an input from an additional device installed in the line (viscometers)

It is understandable that with this kind of accuracy and repeatability, the Coriolis meter has become a standard in the industry.

Which kind of industries are using Coriolis meters?

Nowadays, with its wide acceptance, the Coriolis meter is being used widely in the food industry, chemical plants and oil and gas applications where custody transfer accuracy is a requirement. Other applications can be found in the petroleum , petrochemical, pharmaceutical plants and many more.

What types of applications are common for the Coriolis meter?

- Batch Control

- Blending

- Process Control

- Filling

- Dosing

- Loading and Unloading

- Process Gas Measurement