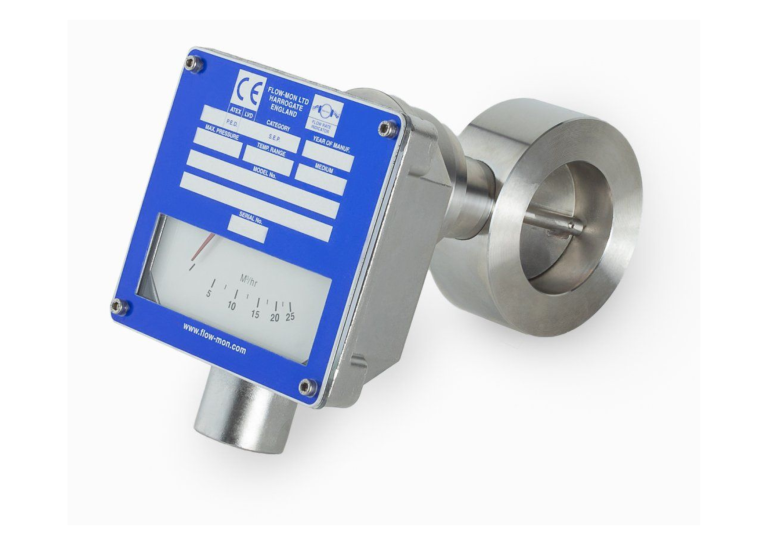

The wafer is designed to mount between two flanges which reduces the weight, size and cost. They are robust, highly versatile and extremely reliable in the harshest of environments.

Description

This unique modular design allows for easy field installation and service. No straight run of pipe is required before or after the monitor, minimizing pressure drop and the installation footprint. Vane-style flow meters have a spring-opposed vane that moves in relation to the flow rate. The fluid forces the vane to move through a contoured opening creating a variable orifice, the greater the flow the larger the orifice becomes for flow to pass. The vane style monitor is spring loaded and allows the vane to return on decreasing flows.

Working on the same principle as Flow-Mon Ltd standard flow monitors the Wafer units are a great addition to the product range. The Wafer Flow Switch is simply mounted between two flange faces. The lighter weight Wafer but still giving robust, reliable indication of flow is easier to install and remove for maintenance. The Wafer Series are considerably cheaper than the flanged equivalent.

Features

- +/- 3% accuracy across the full range

- Direct reading flow rate Indication

- Optional (field adjustable) switch(es)

- Optional non-contact 4-20mA output

- High pressure available

- Mounts easily between ANSI, JIS or DIN flanges

- Mounts in any orientation

- No straight pipe runs required

- Connection sizes from 3” to 12”

- Minimum scale 0-40 LPM

- Maximum scale on request

Applications

- Water

- De-Ionised Water

- Soluble Oils (Glycols)

- Petroleum Based Fluids

- Synthetic Based Fluids

- Coolants

- Corrosive Fluids

- Paints

- Solvents

- Air and Gases